Epoxy flooring offers a resilient and versatile solution for residential, commercial, and industrial floors. Lawrenceville residents and business owners are increasingly turning to epoxy coatings for their floors due to their durability and aesthetic appeal. This high-performance material is known for its ability to withstand heavy foot traffic, resist staining from spills, and is relatively easy to maintain, making it an ideal choice for a wide range of environments.

Lawrenceville’s epoxy flooring services provide a wide array of design options, ranging from solid colors to decorative patterns incorporating flakes and metallic pigments. This flexibility allows for personalization to match any style or branding requirements. Moreover, the preparation and installation process is critical to ensure the flooring’s longevity and performance. Skilled professionals in Lawrenceville are equipped to prepare the concrete surface properly, apply the epoxy, and finish it to the highest standards.

Key Takeaways

- Epoxy flooring is a durable and aesthetically versatile option for various settings in Lawrenceville.

- Proper installation and maintenance of epoxy flooring ensure its longevity and performance.

- Lawrenceville offers professional epoxy flooring services tailored to individual style and functional needs.

Understanding Epoxy Flooring

Epoxy flooring, known for its durability and adaptability, is a popular choice for both residential and commercial spaces, catering to environments varying from garage floors to refined interiors.

Benefits of Epoxy

Epoxy flooring boasts a range of advantages that make it a superior option for various settings. It is notably durable, resisting wear and tear far better than traditional flooring materials like carpet or laminate flooring. This robustness makes it ideal for high-traffic areas and industries with heavy equipment. Moreover, epoxy’s resistance to stains and moisture contributes to its longevity and ease of maintenance.

For aesthetics, epoxy comes in a wide variety of colors and styles, enabling customization that can complement any interior design scheme. Safety is another key benefit, as epoxy can be formulated with anti-slip additives to reduce the risk of accidents in both homes and businesses.

Epoxy Versus Other Materials

| Material | Epoxy | Laminate | Carpet | Vinyl | Hardwood |

|---|---|---|---|---|---|

| Durability | High | Moderate | Low | Moderate to High | High |

| Maintenance | Low | Moderate | High | Moderate | Moderate |

| Cost-Effectiveness | High | Moderate | Low | Moderate | Low |

| Aesthetic Variety | High | High | High | High | Moderate |

Epoxy flooring distinguishes itself from other materials like laminate, carpet, vinyl, and hardwood flooring through its superior durability and ease of maintenance. Unlike carpet, it does not harbor allergens and unlike hardwood, it is not susceptible to warping or scratching. Vinyl flooring provides some competition with a good balance of durability and variety, but epoxy still excels in industrial applications where strength is critical. Laminate flooring offers versatility and is easy to install but is more prone to damage and is not as long-lasting as epoxy.

In summary, epoxy emerges as a highly versatile flooring solution that can endure the rigors of both residential and commercial environments while offering an array of design options.

Preparation and Installation

The installation of Lawrenceville Epoxy Flooring begins with meticulous surface preparation, followed by a precise application process, ensuring a high-quality, durable finish. Professionals execute these steps with craftsmanship, incorporating a variety of concrete floor designs.

Surface Preparation

Initial Assessment: Prior to any work, a thorough assessment of the concrete surface is essential. Professionals look for cracks, chips, and moisture issues that could undermine the epoxy’s adhesion.

-

Cleaning: They begin with cleaning to remove any grease, oil, or existing coatings. Industrial-grade cleaners and degreasers are often used to achieve a pristine surface.

-

Repairing: Any cracks or chips in the concrete must be repaired with patching compounds designed for compatibility with epoxy coatings.

-

Profiling: The concrete surface undergoes a profiling process, which can include acid etching or mechanical grinding, to create the optimal surface roughness for epoxy bonding.

-

Final Inspection: A last inspection ensures all repair materials have set, and the surface is free of contaminants and ready for the application process.

Epoxy Application Process

Primer Coat: The first step is applying a primer coat, which penetrates the concrete for a strong bond. It’s essential for a professional, even application to avoid air bubbles and ensure coverage.

-

Mixing: Epoxy components are mixed with precision according to manufacturer specifications. This process affects the strength of the final product and must be executed with care.

-

Application: Using squeegees, rollers, or sprayers, professionals apply the epoxy coat evenly. The technique used often depends on the specific type of epoxy product and the desired aesthetic of the concrete floor design.

-

Curing: After application, the epoxy must cure for a period specified by the manufacturer, during which time it should not be disturbed.

-

Topcoat: If necessary, a topcoat is applied to add extra durability and to achieve the final desired look, whether it’s glossy, matte, or incorporating decorative chips.

Design and Aesthetics

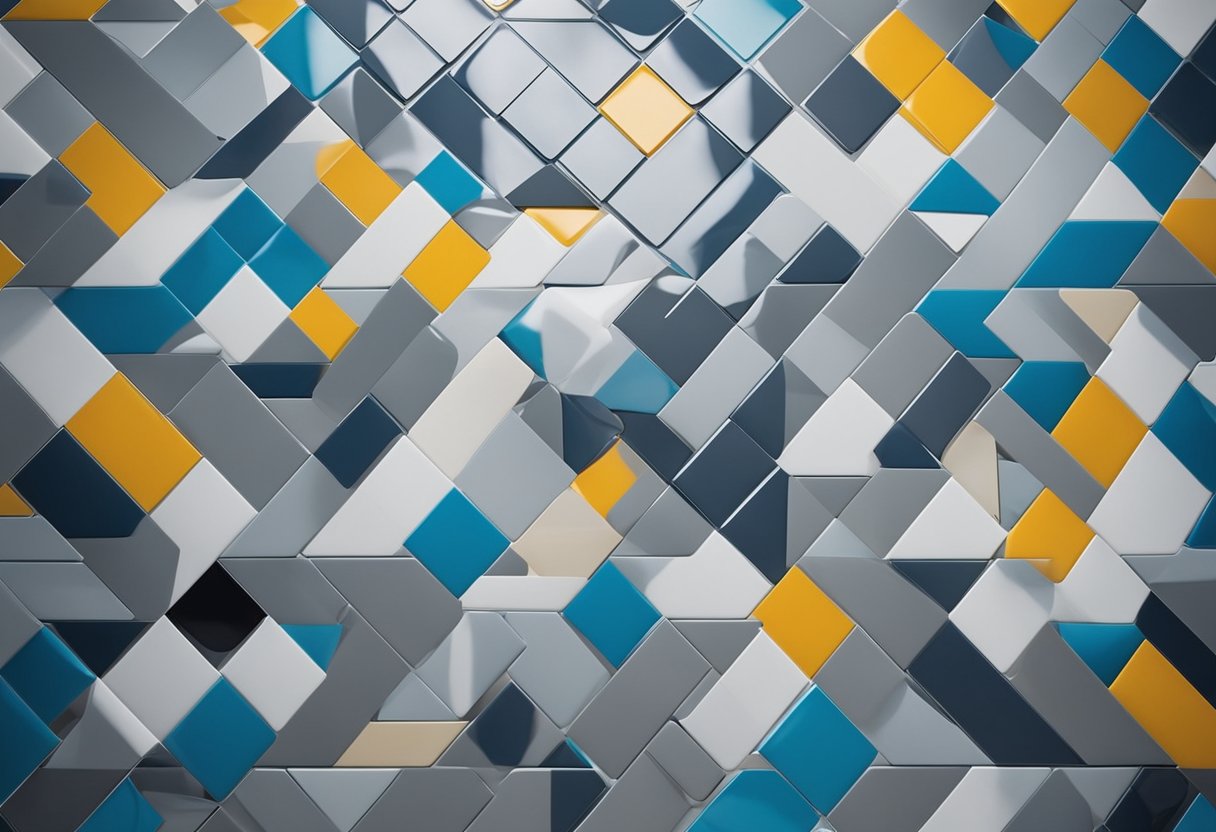

Lawrenceville Epoxy Flooring offers an extensive array of design options catering to various preferences. Their offerings include a range of colors, patterns, and customization possibilities, ensuring that flooring achieves both functional and aesthetic excellence.

Color and Pattern Options

Lawrenceville Epoxy Flooring presents clients with multiple color selections and pattern designs to meet the stylistic demands of each space. Options include:

- Solid Colors: Classic and uniform looks

- Decorative Chips: Adding texture and variation

- Flake Patterns: For a unique, attractive finish

- Metallic Epoxy: Creates a shiny, luxury look

These selections can be applied across various settings, from polished concrete in retail spaces to beautiful garage floors that withstand daily use.

Customized Flooring Solutions

Customized solutions are paramount at Lawrenceville Epoxy Flooring. They focus on tailored services that include:

- Stamped Overlays: Mimic brick, stone, or wood

- Concrete Coatings: Engineered for durability and style

- Floor Coatings: Specifically designed for individual client needs

- Custom Graphics: Incorporating logos or artistic designs

Their expertise allows for epoxy flooring to be adapted for different applications such as patios, where durability meets style.

Lawrenceville Epoxy Flooring ensures that each client can express their style preferences while benefiting from a floor that is as durable as it is visually appealing.

Durability and Maintenance

Epoxy flooring is renowned for its strength and ease of upkeep. Known for being resilient, it withstands daily wear and tear with minimal maintenance required.

Epoxy Longevity

Lawrenceville Epoxy Flooring offers a product that is durable and long-lasting. Under typical conditions, an epoxy floor can last between 10 to 20 years. This lifespan can extend further depending on the volume of foot traffic and the nature of usage. Factors such as the thickness of the epoxy layer and the quality of the installation process play critical roles in extending the durability of the flooring.

- Key Longevity Factors:

- Quality of epoxy used

- Proper installation

- Thickness of the epoxy coat

- Environmental conditions

- Usage patterns

Cleaning and Repair

To maintain the pristine condition of an epoxy floor, routine cleaning is advisable. This involves simple sweeping and occasional mopping with mild cleaners. For stains, a mixture of hot water and ammonia is recommended at a ratio of 120ml per gallon of water.

List of Cleaning Steps:

- Sweep to remove debris.

- Mop with a mild cleaner for general cleaning.

- Use hot water and ammonia solution for stains.

- Avoid acidic and bleach-based cleaners to preserve the surface integrity.

In case of scratches or small damages, the floor can be easily repaired with a patching compound specifically designed for epoxy floors. Lawrenceville Epoxy Flooring ensures that repairs blend seamlessly with the existing surface, maintaining uniformity in appearance.

Epoxy Flooring for Different Settings

Epoxy flooring offers versatile solutions tailored to the specific needs of various settings, from the aesthetic to the functional, ensuring durability and practicality across applications.

Residential Epoxy Solutions

Homeowners often select epoxy coatings for their garages due to the material’s resilience and ease of maintenance. Residential epoxy is not only limited to garages but also extends to basements, kitchens, and living areas which benefit from its longevity and aesthetic appeal. A residential epoxy flooring installation typically features design versatility with a range of colors and textures that complement any home interior.

- Garages: High performance against stains and spillage.

- Living Spaces: A seamless, durable surface that withstands daily activities.

Commercial Epoxy Applications

Commercial epoxy applications are designed to meet the challenging demands of high-traffic areas found in retail spaces, offices, and hospitality industries. These settings require floors that not only reflect a professional image but also offer resistance to heavy foot traffic and repeated cleaning.

- Retail Spaces: An attractive, yet tough surface to cope with constant customer traffic.

- Offices: A combination of functionality and style, with customization options to match corporate branding.

Industrial Epoxy Uses

Industrial facilities prioritize the functional attributes of industrial epoxy flooring. Such environments require surfaces that can withstand heavy machinery, chemical spills, and rigorous cleaning protocols. Epoxy flooring installation in these sectors provides a seamless, impermeable surface that is integral to maintaining workplace safety and hygiene.

- Heavy Machinery Areas: Hard-wearing surfaces that sustain the weight and movement of industrial equipment.

- High-Risk Zones: Floors that resist chemical corrosion and provide enhanced safety with anti-slip properties.

Lawrenceville’s Epoxy Flooring Services

In Lawrenceville, Georgia, epoxy flooring services are provided by a multitude of locally owned companies, each of them dedicated to furnishing both residential and commercial clients with high-quality flooring solutions. Licensed certified epoxy installers are readily available to cater to the diverse needs within the community, offering durability and aesthetic appeal in their installations.

Local Service Providers

- Locally Owned Companies: Lawrenceville is home to various locally owned businesses that specialize in epoxy flooring installations. These entities have built a reputation for reliability and quality work.

- Licensed Installers: Ensuring that flooring solutions meet industry standards, the service providers in Lawrenceville employ experienced, licensed, and certified installers.

- Portfolio of Services:

- Residential Epoxy Flooring: For homeowners looking to enhance their interiors.

- Commercial Installations: Ranging from retail spaces to industrial warehouses, suitable for high traffic and demanding environments.

- Contact Information: To schedule services or consultations, customers can reach out through various “contact us” options provided by the companies.

Customer Support and Guarantees

- Customer Service Excellence: Lawrenceville’s epoxy flooring contractors place a strong emphasis on customer service, striving to understand and meet client expectations fully.

- Assurances Provided:

- Guarantee: Many flooring services come with a guarantee, affirming the confidence in the longevity and quality of their installations.

- Support Channels: Businesses provide comprehensive support through phones, emails, or customer service portals on their websites.

Project Planning and Cost

Successful installation of epoxy flooring in Lawrenceville demands careful planning and a clear understanding of costs and timelines. This ensures that projects are completed efficiently, within budget, and to the highest quality.

Epoxy Flooring Budgeting

Budgeting for Lawrenceville epoxy flooring should account for both materials and labor. Costs can vary widely based on the type of epoxy used, the condition of the existing floor, and the total square footage covered. Free estimates are typically offered by reputable contractors, providing a detailed breakdown of expenses. A typical budget might include:

- Materials: Epoxy resin, hardener, coloring, and decorative chips or quartz.

- Preparation: Cleaning, degreasing, and concrete repair materials.

- Labor: Cost can be influenced by the project complexity and required man-hours.

It’s essential for property owners to be wary of unusually low quotes, which may reflect substandard materials or workmanship. On the other hand, high-quality services might be found among sponsored results but should still be evaluated for value.

Scheduling and Timelines

The duration of an epoxy flooring project in Lawrenceville hinges on the area’s size and the specific epoxy system installed. A standard timeline is often broken down as follows:

- Preparation: 1-2 days for cleaning and floor repairs.

- Application: 1-3 days depending on the number of coats and complexity.

- Curing: A minimum of 72 hours before light foot traffic; full cure can take up to 7 days.

To avoid scheduling conflicts, property owners should communicate their time constraints early in the planning process. It’s advisable for clients to engage contractors with experience and a proven track record to ensure they adhere to the project timeline.

Additional Services and Products

Lawrenceville Epoxy Flooring offers an expanded range of flooring solutions and specialized storage systems tailored to enhance both residential and commercial spaces.

Supplementary Flooring Systems

Beyond epoxy, Lawrenceville Epoxy Flooring provides a variety of supplementary flooring systems to meet diverse needs. Customers can choose from vinyl tile and wood flooring options for areas where aesthetics and comfort are a priority. Each material comes with its own set of benefits, proven to be durable and stylish.

- Vinyl Tile: A cost-effective and versatile option; available in numerous patterns and colors.

- Wood Flooring: Timelessly elegant, bringing warmth and natural beauty to any space.

For customization, Lawrenceville Epoxy Flooring offers stamping and staining services to create unique designs that cater to specific tastes. Those looking for a personalized touch can rely on these techniques:

- Stamping: To emulate textures such as stone or brick for a distinctive look.

- Staining: Imparts rich, deep tones to the flooring, enhancing its original color and grain.

Storage and Organization Solutions

They also specialize in installing comprehensive storage and organization solutions. Lawrenceville Epoxy Flooring recognizes that an organized space is crucial for functionality and therefore integrates systems such as the Monkey Bars Storage System and overhead storage racks.

- Monkey Bars Storage System: This system offers a customizable solution with adjustable bars and hooks to suit various storage needs.

- Overhead Storage Racks: Designed to efficiently use overhead space, ideal for storing seasonal items or equipment that is seldom used.

For clients seeking to improve their staircases, they offer flooring continuity through matching stairs to the chosen flooring system, ensuring a cohesive look throughout the property. Whether it’s the same vinyl, wood, or specially sealed and coated stairs, the aim is to provide a seamless transition from one floor to another.

Technical Aspects of Epoxy Flooring

Epoxy flooring systems provide durable surfaces with high performance for various environments. This section outlines the specific chemical and physical characteristics that epitomize epoxy flooring, along with detailing the procedural methodology for its installation.

Chemical Composition and Properties

Epoxy is essentially a thermosetting resin that, upon curing, forms a robust, impenetrable coating. It’s composed of two primary chemicals: resins and hardeners. The resin component is typically lightweight, clear, and non-toxic, lending to the flooring its desired aesthetics and substrate binding properties. The hardener acts as a catalyst, and when mixed with the resin, triggers the chemical reaction that causes the epoxy to harden. This reaction cross-links the polymer chains, resulting in a flooring that is remarkably resistant to wear, chemical corrosion and has a high tensile strength.

Table of Epoxy Resin Properties

| Property | Description |

|---|---|

| Adhesion | Excellent to concrete and metal surfaces |

| Chemical Resistance | Resistant to acids, alkalis, and solvents |

| Compressive Strength | Outstanding for heavy equipment traffic |

| Durability | Long-lasting with minimal need for repairs |

| Finish | Can be glossy or matte, with color stability |

Installation Techniques and Equipment

The installation of epoxy flooring requires meticulous preparation of the surface. The concrete coatings process starts with the subfloor, which needs to be clean and free of any debris, oils, or previous defective coatings. It’s critical that any cracks or inconsistencies are addressed at this stage, potentially requiring the subfloor to be shimmed or leveled to ensure a uniform application of the epoxy.

Tools and equipment for the installation can vary, but typically include:

- Grinders or shot-blasters to prepare the concrete substrate.

- A notched squeegee for even application of the epoxy resin.

- Rollers to smooth out and distribute the epoxy, removing any entrapped air.

- Mixers to blend the resin and hardener thoroughly before application.

During the installation, adjacent structures such as baseboard moldings and cabinetry must be protected or temporarily removed to prevent damage or contamination. It is essential to maintain a controlled environment, as temperature and humidity can significantly influence the curing process and final outcome of the epoxy coating.

Aftercare and Enhancement

Proper aftercare enhances the durability and appearance of epoxy flooring, while refinishing and upgrades can revive its aesthetic appeal. Lawrenceville Epoxy Flooring emphasizes the importance of regular maintenance and timely repairs.

Maintenance Programs

Routine Maintenance: Lawrenceville Epoxy Flooring recommends daily sweeping and weekly mopping to maintain the flooring’s luster. Avoid abrasive pads and harsh chemicals, opt for a soft cloth or mop and a mild cleaner instead.

Preventative Measures: Place mats at entryways to minimize dirt and grit, which can cause scratches, especially on surfaces like oak and hickory hardwood flooring underlying the epoxy.

Repair Practices: Prompt attention to chips and cracks is crucial. Small repairs can be made using an epoxy patching compound, ensuring the flooring maintains its integrity and appearance.

Epoxy Refinishing and Upgrades

Refinishing Process: When epoxy flooring begins to show signs of wear, refinishing is an option. The process involves sanding the top layer and applying a new coat of epoxy, which restores shine and provides additional protection.

Upgrade Options: Lawrenceville Epoxy Flooring offers upgrades such as anti-slip additives and UV-resistant topcoats. These enhancements not only improve the functionality and longevity of the flooring but also adapt it to the specific needs of the environment.

Frequently Asked Questions

This section addresses common inquiries regarding Lawrenceville Epoxy Flooring, providing clarity on costs, durability, application, and maintenance.

What factors influence the cost of epoxy flooring installation?

The cost of epoxy flooring installation varies based on several factors including the size of the area, the type of epoxy used, the complexity of the design, and the condition of the existing floor. Additionally, labor costs can affect the overall price.

What are some potential drawbacks of choosing epoxy flooring for a home or business?

Potential drawbacks of epoxy flooring include its susceptibility to damage from UV rays, which can lead to yellowing over time. Epoxy floors can also be slippery when wet and may require additives for added traction. Proper installation by experienced professionals is crucial to avoid these issues.

How does the lifespan of epoxy flooring compare to other flooring options?

Epoxy flooring is known for its durability and can last anywhere from 10 to 20 years with proper installation and maintenance. This longevity often surpasses that of many conventional flooring materials, such as carpet or vinyl.

Can epoxy flooring be applied over an existing concrete surface?

Epoxy flooring can indeed be applied over an existing concrete surface, provided the concrete is properly prepared. This includes repairing any cracks, cleaning the surface thoroughly, and ensuring the concrete is level to achieve optimal adhesion and finish.

What is the average cost per square foot for installing epoxy flooring?

The average cost for installing epoxy flooring ranges from $3 to $12 per square foot. Prices can vary based on the type of epoxy used, the condition of the floor, and the complexity of the project.

How do maintenance requirements of epoxy flooring compare to traditional flooring materials?

Epoxy flooring requires minimal maintenance compared to traditional flooring materials. It is easy to clean, resistant to stains, and does not require regular waxing or sealing. However, it must be kept free of grit and sharp objects to prevent scratching.