East Liberty Epoxy Flooring presents a comprehensive solution for those seeking durable, attractive, and low-maintenance flooring options. As a versatile material, epoxy serves as an excellent choice for both residential and commercial spaces due to its robustness and the variety of finishes available. This type of flooring involves applying a thermosetting resin that, once cured, creates a hard, protective coating over concrete floors. Not only does it offer resistance to wear and tear, but it also provides a sleek, high-gloss finish that can transform the aesthetics of any space.

In the realm of flooring, epoxy is prized for its longevity and ease of maintenance, making it a practical investment for many property owners. With the correct installation and care, epoxy flooring can withstand heavy foot traffic and industrial activity, thus preserving its appearance and functionality for years. The customization options with colors, patterns, and textures allow for the creation of unique designs tailored to specific tastes or branding requirements. Additionally, its seamless surface is imperative for environments that require hygienic conditions, such as hospitals and food processing facilities, making it a preferred option in varied industries.

Key Takeaways

- Epoxy flooring offers a durable solution for both commercial and residential spaces, ensuring longevity and resistance to heavy use.

- The material allows for extensive design customization, aiding in the creation of unique floor aesthetics.

- Easy maintenance and hygienic properties of epoxy make it suitable for diverse environments that prioritize cleanliness.

Understanding Epoxy Flooring

Epoxy flooring is a resilient and versatile solution for a broad range of flooring applications, known for its strong adhesive properties, durability, and chemical resistance.

Components and Chemical Properties

Epoxy floor coatings are comprised primarily of two parts: resin and a hardener. When mixed together, they undergo a chemical reaction known as curing. This process transforms the liquid epoxy into a hard, durable surface that bonds securely to concrete substrates. The resulting floor coating is resistant to chemicals, stains, and abrasions, making it exceptionally long-lasting.

- Resin: Provides the glossy finish and color of the floor.

- Hardener: Acts as a catalyst, ensuring that the epoxy cures and hardens properly.

Types of Epoxy Coatings and Their Applications

There is a variety of epoxy coatings designed for different uses, each suitable for specific projects.

- Self-leveling Epoxy: Ideal for creating a smooth and level surface on new or old concrete.

- Graveled Epoxy: Offers decorative patterns that can incorporate logos, brand names, or directional details into the flooring.

- Epoxy Mortar: The toughest of the epoxy floor coatings and is used in heavy-industrial applications.

- Anti-static Epoxy (ESD-resistant): Designed for use in areas where a static-sensitive environment is critical, like clean rooms or electronic manufacturing facilities.

These coatings are fitting for environments such as garages, warehouses, commercial spaces, and manufacturing facilities, where flooring durability and maintenance are a priority.

Epoxy vs Other Flooring Solutions

Epoxy flooring is often compared to other types of floor coatings, each having its own set of characteristics and benefits.

- Polyurethane: Offers a higher resistance to UV light and is more flexible compared to epoxy.

- Polyaspartic: Cures very quickly and is usable across a wide range of temperatures.

- Polyurea: Similar to polyaspartic coatings, with fast curing times and flexibility.

- Paint: While easier to apply, it does not offer the same level of durability or chemical resistance as epoxy.

When compared to alternatives, epoxy flooring stands out for its balance of cost-efficiency, durability, and maintenance requirements, making it a solid choice for a variety of flooring projects.

Design and Aesthetic Choices

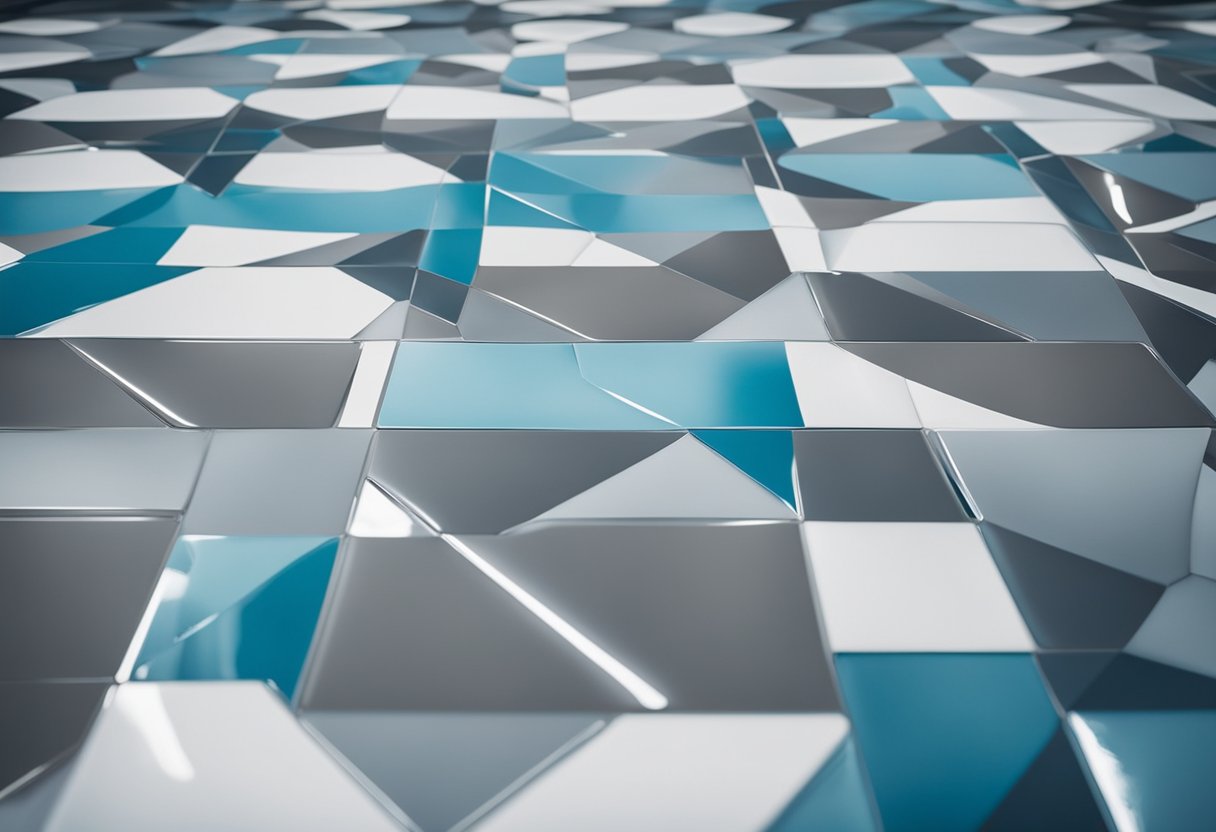

Epoxy flooring offers a wide range of design possibilities, enabling the creation of durable and visually appealing surfaces. The right selection of colors, patterns, and finishes can transform spaces and meet diverse style preferences.

Colors and Patterns Selection

Choosing colors and patterns for epoxy flooring is an essential step in creating a custom look. Clients can select from a spectrum ranging from subtle hues to vibrant tones, which can be arranged in various patterns such as:

- Geometric shapes: squares, triangles, or a mix for a modern look

- Natural motifs: mimicking marble or granite for an elegant touch

- Custom designs: logos or specific art for a personalized space

The choice of colors and patterns can influence the mood of an environment, whether aiming for calming blues or energizing reds.

Texture and Surface Finishes

The texture and surface finishes of epoxy flooring impact both aesthetics and functionality. Options include:

- Smooth surface: a clean and sleek look with high reflectivity

- Slip-resistant texture: essential for safety, especially in high-traffic or wet areas

Finishes range from matte to high gloss, offering varying degrees of shine and style adaptability. When considering finishes, one must weigh the desired aesthetic against practical requirements like maintenance and durability.

Epoxy Flooring Installation

Epoxy flooring installation is a precise process requiring careful surface preparation, specific application techniques, and an appropriate curing period to ensure durability and a smooth finish.

Surface Preparation Steps

Before applying epoxy, it’s critical to have a clean, dry, and level surface. The installation process begins with thorough floor prep to maximize the adherence and longevity of the epoxy coating.

- Cleaning: Start by removing all dirt, grease, and debris from the concrete surface. Chemical solvents may be needed to break down tough stains.

- Repairing Cracks: Inspect the concrete for any cracks or damage. Use a quality concrete filler to repair these imperfections and sand the area until smooth.

- Testing for Moisture: Conduct a moisture test to ensure the concrete is completely dry. Excessive moisture can impede the curing process of the epoxy.

- Profiling the Surface: To improve the bond between concrete and epoxy, the surface needs to be slightly porous. This can be achieved by acid etching or mechanical means such as grinding.

Applying Epoxy: Techniques and Tips

Proper application of epoxy requires precision to ensure an even, thick layer that is hard to the touch and resistant to spills.

- Mixing the Epoxy: Follow the manufacturer’s instructions when mixing the components of your epoxy flooring kit. Inconsistent mixing can lead to a poor finish.

- Application Tools: Use a roller or a notched squeegee for even distribution. For thicker coats, multiple layers may be necessary, allowing each to partially cure before the next is applied.

- Working Time: Epoxy has a limited window for application before it begins to set. Keep an eye on the clock to ensure a consistent finish.

- Edges and Corners: Apply epoxy carefully along edges and in corners to avoid buildup, using a brush for precision.

Curing Time and Post-Installation Care

The longevity of epoxy flooring largely depends on the cure time and the care it receives post-installation.

- Curing Process: Allow the epoxy to cure as directed, typically for at least 24 hours before allowing light foot traffic. Full cure can take up to 7 days.

- Temperature and Humidity: Maintain a consistent temperature and humidity level as recommended by the epoxy kit to ensure optimal curing.

- Aftercare: Once cured, keep the surface clean with regular maintenance. Epoxy floors are resilient but can benefit from immediate cleaning of any spills to prevent staining.

Maintenance and Longevity

Proper care and timely repair are critical to extending the lifespan of East Liberty Epoxy Flooring. They ensure durability and optimal performance, particularly in high-traffic environments or areas prone to spills and abrasion.

Routine Cleaning and Maintenance

Regular maintenance for epoxy floors involves:

- Sweeping: Daily sweeping prevents the buildup of dust and debris.

- Mopping: Weekly mopping with a pH-neutral cleaner retains floor shine and prevents grime.

- Spot Cleaning: Immediate attention to spills prevents staining and maintain a clean room environment.

A maintenance schedule can look like this:

| Frequency | Action |

|---|---|

| Daily | Sweep |

| Weekly | Mop with pH-neutral cleaner |

| As Needed | Spot clean spills and stains |

Damage Prevention and Repair

To preserve the epoxy flooring’s integrity:

- Foot Traffic: Utilize area rugs or mats in high-traffic zones to reduce wear.

- Heavy Loads: Use protective pads under heavy equipment to prevent scratches and abrasion.

- Repairing Damage: Address cracks and peeling promptly to prevent further deterioration. This typically involves cleaning the affected area, filling the cracks, and resealing if necessary.

Epoxy flooring is lauded for its low-maintenance qualities. Still, occasional repairs are necessary to address any damage from rigorous use to maintain the flooring’s longevity and performance.

Advantages of Epoxy Flooring

Epoxy flooring is recognized for its superior durability and cost-effectiveness, providing an optimal balance between performance and value.

Durability and Performance

The resilience of epoxy flooring to harsh environments is one of its most significant advantages. This type of flooring is designed to withstand heavy foot traffic and abrasion, ensuring a long-lasting surface. Its chemical resistance adds to the flooring’s robustness, making it suitable for commercial and industrial settings where spills are common. Notably, epoxy flooring possesses UV resistance, which helps maintain its appearance and integrity when exposed to sunlight. Slip resistance can be enhanced by adding aggregates, rendering it safer in wet conditions.

| Epoxy Flooring Attribute | Benefit |

|---|---|

| Chemical Resistance | Prevents deterioration from spills. |

| UV Resistance | Protects color and structural integrity. |

| Slip Resistance | Increases safety in high-moisture areas. |

Cost-Efficiency and Value

When considering the cost of flooring, epoxy is a comparatively economical option. It usually requires fewer layers than other types of industrial flooring, which reduces both material and labor costs. The longevity of epoxy flooring diminishes the need for frequent reapplication, saving money in the long term. Additionally, the low maintenance requirements of epoxy flooring further amplify its value, as it rarely necessitates expensive upkeep or repairs.

| Factor | Impact on Cost |

|---|---|

| Less material | Reduces initial cost. |

| Durability | Lowers long-term expenses. |

| Maintenance | Minimizes ongoing costs. |

Considerations for Specific Environments

Choosing the right epoxy flooring for different settings is crucial to meet both functional and aesthetic needs. Specific factors like moisture, chemical exposure, UV light, and required slip resistance vary greatly between environments, affecting the selection process.

Industrial and Commercial Use

Moisture Resistance:

For environments such as manufacturing plants and warehouses, epoxy flooring must withstand frequent exposure to moisture. Floors in these areas are prone to spills and the cleaning process often involves water, making it necessary for the epoxy to provide an impermeable surface to prevent damage.

| Environment | Moisture Concerns |

|---|---|

| Shop Floors | High exposure to liquids and regular cleaning |

| Clean Rooms | Strict control of humidity and contamination |

| Manufacturing | Heavy-duty resistance to industrial spills |

| Warehouses | Durable against routine cleaning and accidents |

Chemical and UV Resistance:

Industrial settings often expose floors to harsh chemicals and, in some cases, ultraviolet light, which can degrade standard flooring materials.

- Chemical Resistance: Factories require floors that resist corrosion from industrial chemicals and solvents to ensure longevity and safety.

- UV Resistance: For commercial spaces with significant sun exposure, UV-resistant epoxy helps in maintaining the floor’s integrity and appearance.

Slip Resistance:

Given that safety is paramount in commercial spaces:

- For shop floors, a non-slip surface is critical to minimize the risk of accidents.

- In warehouses with heavy machinery traffic, slip-resistant textures help promote a safer work environment.

Residential Applications

Homeowner Specifics:

Epoxy flooring in residential spaces, such as garages, prioritizes aesthetics while balancing functionality for the homeowner’s lifestyle.

- Garages: Homeowners require a balance between slip resistance for safety and ease of cleaning for maintenance.

- DIY Projects: The epoxy selected for DIY applications should offer straightforward installation with robust features to handle home-based activities.

Environmental Considerations:

Residential epoxy flooring should be tailored to handle less severe conditions compared to industrial settings, while still offering durability and resistance:

- Garages: Often subject to temperature fluctuations and potential chemical spills from vehicles which necessitates protective features.

- General Home Use: The epoxy should resist common household chemicals and provide sufficient UV resistance if applied in sun-exposed areas.

It’s apparent that the choice of epoxy flooring should be a thoughtful decision shaped by the specific requirements of the space in question. Whether for industrial strength and safety or residential functionality and aesthetics, the correct epoxy flooring will serve its purpose effectively.

How to Choose the Right Epoxy Flooring

When selecting epoxy flooring, one should consider the project scope, whether it is a do-it-yourself (DIY) endeavor or for a commercial space. DIY kits are available for homeowners looking to apply epoxy coating in garages or small areas. However, for larger or more demanding environments, such as commercial spaces, professional-grade products and installation may be required.

Epoxy flooring comes in various styles that can influence the aesthetic and functional aspects of a space. Consider the desired appearance and how it complements the existing decor. Performance is another critical factor; evaluate the durability, resistance to chemicals and spills, and the ease of maintenance before making a choice.

Key Considerations:

- Project Type: DIY projects can utilize simpler kits, while commercial spaces might need specialized epoxy systems.

- Area Usage: Garages demand abrasion-resistant coatings, whereas commercial spaces may need slip-resistant features.

Epoxy Flooring Styles:

- Self-leveling: Ideal for uneven surfaces, providing a smooth finish.

- Graveled: Offers enhanced decorative appearance with various textures.

- Terrazzo: Aesthetically pleasing option for high-visibility areas.

Maintenance & Performance:

Maintenance is inversely related to performance. High-quality epoxy flooring requires less frequent maintenance, while basic coatings may need regular upkeep to preserve their appearance and functionality.

| Property | Importance for DIY | Importance for Commercial |

|---|---|---|

| Durability | High | Very High |

| Chemical Resistance | Moderate | High |

| Aesthetic Appeal | High | Moderate to High |

| Maintenance Level | Low to Moderate | Low |

In conclusion, one must carefully assess their specific needs, the flooring’s intended use, and the conditions it will face to ensure that they select the most appropriate epoxy flooring solution.

Epoxy Flooring Pros and Cons

Epoxy flooring is a popular choice for both residential and commercial spaces due to its durability and performance. Pros of epoxy flooring include:

- Longevity: Epoxy flooring typically lasts longer than many other flooring types, thanks to its resistance to wear and tear.

- Maintenance: It is relatively easy to clean and requires minimal upkeep, aside from occasional resealing.

- Aesthetics: Epoxy floors provide a seamless and professional look, available in various colors and patterns.

- Performance: Epoxy flooring is resistant to stains, impacts, and chemicals, making it ideal for high-traffic areas.

- Cost-Effective: Over time, the long-term cost benefits of epoxy flooring are significant given its durability.

On the flip side, the Cons include:

- Cost: The initial installation cost can be higher than other flooring options, particularly for high-quality finishes.

- Slippery When Wet: Epoxy can be slippery when wet, which may require additional safety measures, such as texturing.

- DIY Challenges: Installation might be more complex than other flooring types, possibly necessitating professional help.

- Maintenance: In the event of damage, sometimes the entire floor must be recoated, which can be inconvenient and costly.

When considering epoxy flooring, weighing these factors will help determine if it’s the right flooring solution for one’s needs. It’s not a one-size-fits-all solution, but for many, the benefits of epoxy flooring outweigh the drawbacks.

Trends in Epoxy Flooring

Epoxy flooring has become increasingly popular for its durability and versatility. New trends are shaping the industry, focusing on aesthetics, customization, and functionality.

Styles and Colors:

The demand for a wider range of colors and styles has led to epoxy flooring products that mimic natural stone, wood, and even metallic finishes. Consumers can choose from a broad spectrum of shades, ranging from subtle earth tones to vibrant hues.

Patterns and Aesthetics:

Epoxy floors are no longer limited to industrial spaces. Residences and commercial settings now feature intricate patterns and textures. Geometric and bespoke designs are trending, allowing spaces to reflect individual styles and preferences.

Finishes:

Matte, gloss, and satin finishes offer different levels of sheen, impacting the floor’s visual appeal and maintenance requirements. Matte finishes hide scratches better and provide a contemporary look, whereas gloss finishes enhance color depth and brightness.

DIY Popularity:

The DIY community has embraced epoxy flooring due to its accessibility and transformative power. However, achieving a professional look requires precise preparation and application. Recent product innovations cater to this market with more user-friendly options.

In conclusion, today’s epoxy flooring trends cater to a wide array of tastes, from understated elegance to bold statements. They offer durability, style, and a touch of personalization to any space.

Frequently Asked Questions

Selecting the right epoxy flooring service is critical for ensuring a quality finish and long-term durability. These FAQs address key points about East Liberty Epoxy Flooring to guide potential customers in their decision-making process.

What factors should I consider when reading reviews about epoxy flooring services?

When evaluating reviews, consider the service provider’s timeliness, quality of materials, customer service, and the longevity of their epoxy applications. Reviews that mention these specifics provide insight into the actual performance and reliability of the flooring services.

How does the longevity of epoxy flooring compare to traditional concrete floors?

Epoxy flooring typically lasts anywhere from 5 to 10 years longer than untreated concrete floors. It’s highly resistant to wear, chemicals, and stains, making it a durable choice for both commercial and residential spaces.

What are the advantages of choosing epoxy flooring over tile flooring in terms of cost?

Epoxy flooring is generally more cost-effective than tile flooring both in initial installation and maintenance costs. Epoxy offers a seamless finish, eliminating the need for grouting and the associated upkeep, which can lead to greater savings over time.

What is the range of color options available for epoxy flooring installations?

Epoxy flooring comes in a wide variety of colors and designs, including solid colors, multi-colored flakes, and metallic designs. Clients can choose a color or blend that complements their space, whether it’s for a commercial, industrial, or residential area.

How do professional epoxy flooring solutions, like those from Bolcor Flooring, differ from DIY alternatives?

Professional epoxy flooring solutions use high-grade resins and proper surface preparation to ensure a smooth application and curing process. DIY kits may lack in the quality of materials and the expertise required for a durable finish. Professionals also provide warranties for their workmanship.

What maintenance is required to ensure the durability of an epoxy floor?

Regular cleaning with a mild detergent and avoiding abrasive chemicals will help maintain an epoxy floor’s luster and prevent scratches or wear. Periodic resealing may be required depending on foot traffic and use to ensure the floor remains in optimal condition.