When considering a flooring upgrade or installation for a residential, commercial, or industrial space, Bloomfield Epoxy Flooring emerges as a top contender recognized for its professional approach and the quality results it delivers. Epoxy flooring systems are known for their durability, providing a tough, stain-resistant surface ideal for high-traffic areas. As an appealing option for various settings, epoxy floors can withstand the demands of garages, warehouses, and showrooms, offering both functionality and improved aesthetics.

Beyond its resilience, epoxy flooring provides a seamless and sleek look that can be customized with colors, patterns, and textures to match any design vision. This customizable nature extends to its safety features, with options for slip-resistant additives that make it a safer flooring choice in workplaces and homes. Moreover, the installation process, requiring careful surface preparation, is best handled by experienced professionals like those at Bloomfield Epoxy Flooring to ensure the highest level of performance and longevity from the investment.

Key Takeaways

- Bloomfield Epoxy Flooring offers professional, quality installations ensuring durable and aesthetically pleasing results.

- Customizable design options and safety features make epoxy flooring suitable for various applications and environments.

- Proper installation by experts is essential for maximizing the long-term value and performance of epoxy flooring systems.

Understanding Epoxy Flooring

Epoxy flooring stands as a premier choice for its durability and aesthetics, offering long-lasting surfaces for various environments. It merges strength with low maintenance, presenting an ideal solution for industrial, commercial, and residential spaces.

Composition and Properties

Epoxy flooring systems comprise two main components: a resin and a hardener. When mixed, they undergo a chemical reaction that results in a rigid plastic material known for its strength and durability. This seamless flooring is resistant to wear, making it suitable for heavy-duty environments.

- Resin: Provides the floor’s surface with a smooth and shiny finish.

- Hardeners: Act to cure the resin, creating a hard and durable surface.

Benefits of Epoxy Coatings

Epoxy coatings offer a multitude of benefits, including their low-maintenance nature and the beauty they add to a floor. They create a seamless and long-lasting surface that can withstand substantial stress, making them fit for garages, warehouses, and hospitals.

- Durability: Epoxy floors resist chemicals, stains, and abrasions.

- Beauty: They provide a lustrous finish that can complement any design aesthetic.

- Low-Maintenance: These floors are easy to clean, requiring only minimal upkeep.

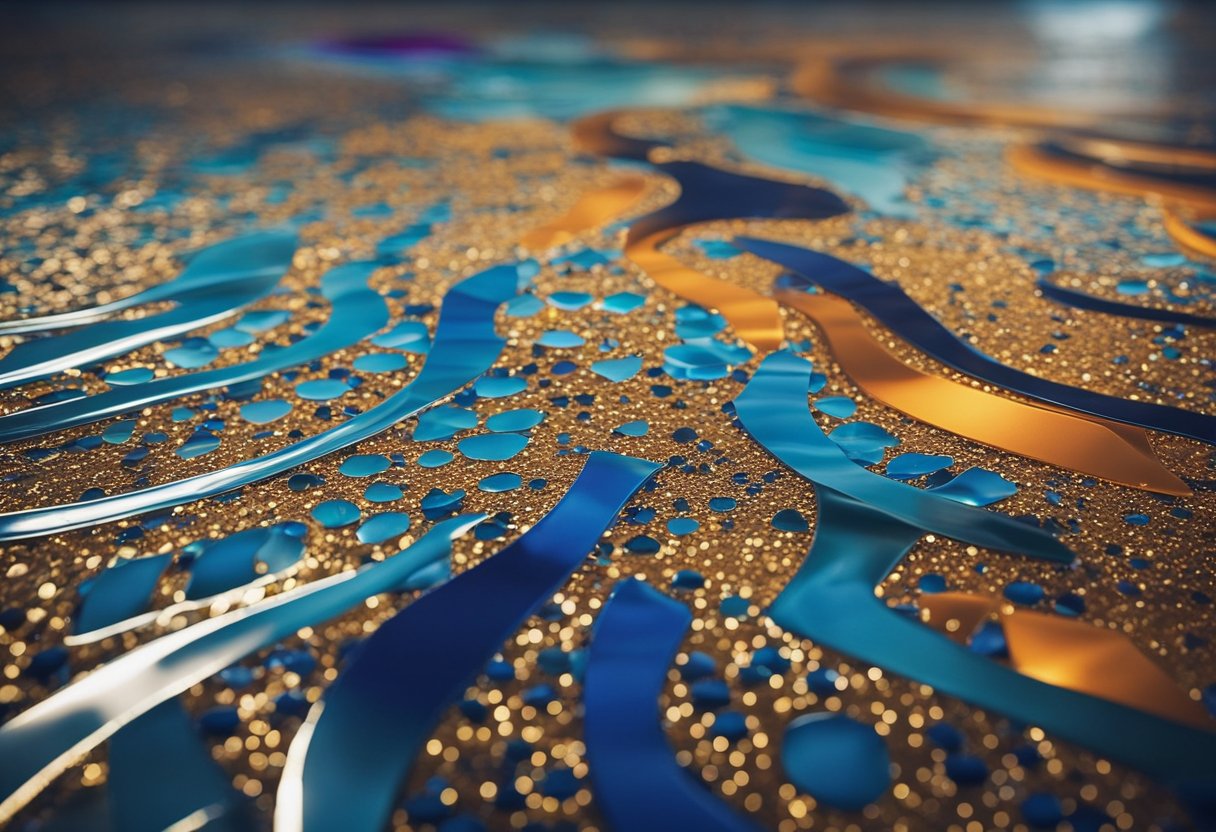

Types of Epoxy Flooring Systems

There are diverse types of epoxy flooring systems, each designed to meet specific needs. Industrial epoxy flooring is engineered for its resilience against rigorous activities, while residential epoxy flooring enhances a home’s visual appeal and functionality. Commercial epoxy flooring offers both strength and an impressive look to businesses. Metallic epoxy floor coatings provide a unique, decorative finish that mimics marble and other high-end materials.

- Industrial Epoxy Flooring: Built for high traffic and heavy machinery.

- Residential Epoxy Flooring: Combines durability with decorative elements.

- Commercial Epoxy Flooring: Provides a balance of aesthetic appeal and strength.

- Metallic Epoxy Floor Coatings: Creates a three-dimensional look with depth and shimmer.

Preparation and Installation Process

The preparation and installation of Bloomfield Epoxy Flooring involve meticulous surface preparation, employing precise installation techniques, and understanding the importance of curing time and aftercare to ensure the durability and aesthetic appeal of the flooring.

Surface Preparation

Before epoxy floor coating can be applied, the concrete surface must be thoroughly prepared to ensure optimal adherence. The process involves:

- Cleaning: Removal of all dirt, grease, and debris from the concrete surface.

- Repairing: Filling in cracks and chips in the concrete to create a smooth substrate.

- Profiling: Diamond grinding or shot blasting to open up the pores of the concrete for better bonding.

Installation Techniques

Professionals apply epoxy floor coating with expert craftsmanship to achieve a neat and uniform surface. The installation process is typically quick and includes steps such as:

- Primer Coat: Application of a primer to enhance the bond between the concrete and epoxy layers.

- Base Coat: Spreading the epoxy mixture evenly across the surface.

- Decorative Elements: Adding color flakes or other decorative details if desired.

- Top Coat: Sealing the epoxy with a topcoat to protect the finish and add extra durability.

Curing Time and Aftercare

Following the installation, the curing phase is critical for epoxy flooring:

- Curing Time: Usually ranges from 24 to 72 hours before the floor can handle light traffic.

- Full Cure: The floor typically reaches full strength within 7 days.

Aftercare is straightforward with epoxy flooring, offering easy maintenance to preserve its condition:

- Regular Cleaning: Sweeping and mopping to maintain cleanliness.

- Avoid Heavy Impact: Keeping the floor free from heavy or sharp objects that can damage the surface.

Epoxy Flooring Uses and Applications

Epoxy flooring, recognized for its durability and aesthetic appeal, is a versatile flooring solution suitable across various settings that demand resilience against foot traffic, heavy machinery, and potential spills.

Residential Applications

Epoxy flooring is an increasingly popular choice for areas in homes like garages, kitchens, and basements. In garages, its resistance to oil and chemical spills makes for an easy-to-clean surface that can withstand the rigors of heavy vehicular traffic. For kitchens and basements, the seamless and water-resistant nature of epoxy provides a hygienic surface that combats mold and mildew, while offering a range of decorative finishes to complement home aesthetics.

Commercial Applications

Within commercial environments, epoxy flooring serves well in retail spaces, offices, and restaurants. Its versatility allows for custom designs that can enhance brand identity in retail spaces, while the durability accommodates high foot traffic in offices. Restaurants benefit from epoxy’s hygienic qualities, resisting stains and facilitating easy clean-up of spills, thus maintaining hygiene and cleanliness.

Industrial Applications

The industrial sector values epoxy flooring for its ability to support environments laden with heavy machinery and intense operational demands. Warehouses and manufacturing plants utilize epoxy coatings for their ability to sustain heavy loads and provide a safe, non-slip surface. Its robustness ensures a long-lasting floor that can endure the stress of continual use with minimal maintenance.

Specialty Applications

Areas that require stringent sanitation and durability, such as hospitals and healthcare facilities, often employ epoxy flooring. The seamless finish aids in maintaining a sterile environment crucial for patient care. In commercial kitchens and food preparation areas, epoxy flooring is favored for its ease of cleaning and resistance to high temperatures and corrosive substances, aligning with the high standards of cleanliness expected in the food industry.

Design and Aesthetics

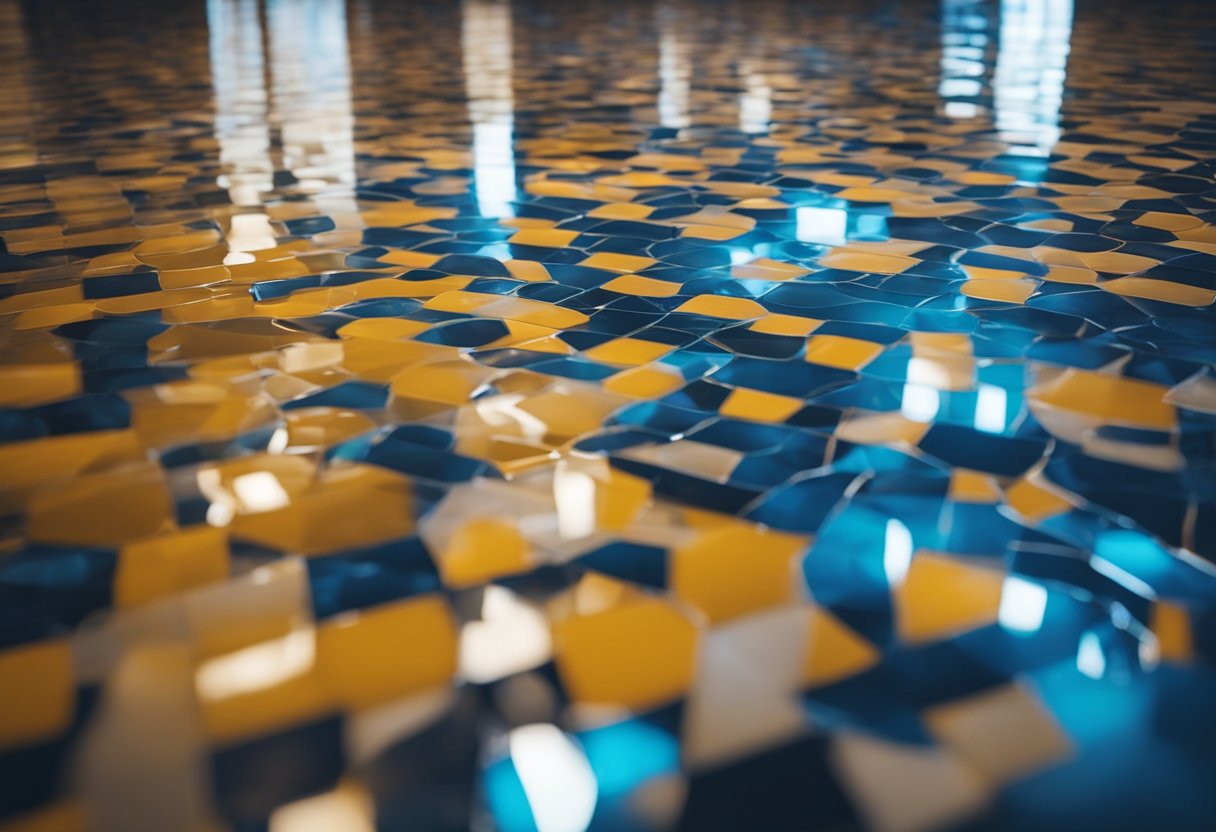

Bloomfield Epoxy Flooring offers an array of design choices that not only enhance the durability of floors but also cater to the aesthetic preferences of a diverse clientele. One can choose from various textures, colors, and custom designs, including embedded logos and intricate patterns, to achieve a unique look that aligns with their style and branding needs.

Choosing the Right Texture and Color

When selecting epoxy flooring, understanding the impact of texture and color is crucial. Texture options range from smooth to anti-slip surfaces, tailored to different functional requirements.

| Texture Types | Features | Applications |

|---|---|---|

| Smooth | Easy to clean, high-gloss finish | Commercial spaces, Showrooms |

| Anti-slip | Adds friction, reduces slip hazards | Industrial areas, Garages |

Color plays a vital role in setting the atmosphere of a space. Bloomfield Epoxy Flooring offers a spectrum of colors to suit various design preferences.

- Neutral tones (e.g., beige, grey) for a minimalist, modern appeal.

- Bold colors (e.g., red, blue) to make a statement or delineate areas.

- Blend of colors to create marbling effects, enhancing the beauty of the floor.

Incorporating Logos and Patterns

For businesses seeking to reinforce their brand, incorporating logos into epoxy flooring is a popular choice. Bloomfield Epoxy Flooring specializes in embedding custom logos with precision.

- High-resolution custom designs are achievable.

- Utilizing contrasting colors for logos ensures visibility and impact.

Patterns are another method to convey style and enhance the beauty of the space. From geometric shapes to intricate designs, patterns add depth and character to epoxy floors. Customized options allow clients to infuse personal or brand identity into the floor’s design.

Safety and Maintenance

Ensuring safety and simplifying maintenance are at the forefront of Bloomfield Epoxy Flooring solutions. Designed with family and business environments in mind, these floors incorporate features that provide stability and hygiene while remaining easy to clean.

Non-Slip Additives and Safety Features

For areas with high foot traffic or potential for spills, Bloomfield Epoxy Flooring incorporates non-slip additives to improve safety. These additives provide traction even when the surface is wet, reducing the risk of slips and falls, thereby ensuring the well-being of families and employees. Additionally, the option to customize the level of grip based on specific needs allows for tailored safety solutions.

Cleaning and Maintenance Guidelines

Maintenance of epoxy floors is straightforward and cost-effective. To preserve hygiene and appearance, use the following guidelines:

- Daily Maintenance:

- Sweep the floor with a soft-bristle broom or use a dust mop to remove loose particles.

- Clean spills immediately to prevent slips and maintain hygiene.

- Weekly Maintenance:

- Mop the floor using a microfiber mop and a mild cleaner designed for epoxy flooring.

- For stubborn stains, use a soft deck brush and the appropriate cleaning solution.

- Periodic Maintenance:

- Deep clean the floors quarterly or as needed to remove buildup and maintain the easy-to-clean surface.

Epoxy flooring offers a durable, hygienic, and safe surface suitable for various settings, simplifying maintenance routines while enhancing overall safety.

Durability and Performance

Bloomfield Epoxy Flooring offers robust solutions characterized by their strength and resilience, ensuring long-lasting performance even under challenging conditions.

Wear Resistance and Longevity

Epoxy flooring from Bloomfield is designed with wear resistance in mind, enabling it to withstand heavy foot traffic and continuous use without showing signs of degradation. Due to its hard-wearing surface, customers report significantly fewer scratches, dents, and wear patterns over time.

- Durability: Exceptionally strong epoxy bonds contribute to a durable, long-lasting floor.

- Longevity: Floors typically maintain their integrity and appearance for years without the need for frequent repairs or replacement.

Chemical and Temperature Resilience

The formulations used by Bloomfield Epoxy Flooring confer notable chemical resistance, allowing these floors to resist damages from spills and contact with harsh substances.

- Chemical Resistance: Epoxy floors resist a variety of chemicals like acids, alkalis, and solvents.

- Temperature Fluctuations: Engineered to endure extreme temperatures, Bloomfield’s floors maintain their form and function without cracking or peeling.

The company’s flooring solutions are rigorously tested to ensure they meet high standards for both chemical and temperature resilience, confirming the brand’s commitment to quality and performance.

Selecting the Right Epoxy Flooring Contractor

When planning an epoxy flooring installation, selecting the right contractor is crucial. Their expertise, licensing, and approach to customer satisfaction will directly impact the success of your home project.

Criteria for Choosing a Contractor

Licensing and Experience: Ensure the contractors you are considering are licensed to perform epoxy flooring services. Licenses indicate they have met industry and local standards. Experience is just as important; experienced contractors have a track record that can be assessed through past work examples and customer testimonials.

- Reputation: Look for contractors with positive customer feedback emphasizing reliability and professionalism.

- Local Pros: Hiring local contractors can be beneficial as they are familiar with the region’s building codes and sourcing materials.

Budget and Project Considerations

Affordability: It’s essential to find a balance between cost and quality. Gather multiple quotes to compare and understand the market rate.

| Consideration | Description |

|---|---|

| Material Cost | High-quality epoxy offers durability but may affect pricing. |

| Scope of Work | The project’s complexity will influence the labor cost. |

| Contractor’s Quote | Detailed quotes reveal contractors’ transparency and honesty. |

Budget-Friendly Options: Some contractors offer various options to match your budget without compromising on the essential quality. Discussing your budget upfront can prevent future misunderstandings and ensure the project remains affordable.

Epoxy Flooring Costs and Value

When considering epoxy flooring for a property, it’s pivotal to weigh the expense against the long-term value it provides. Initial costs vary depending on factors like area size, condition of the existing floor, and desired customization.

Pricing Breakdown:

- Material Costs: Affordable options start from $3 to $7 per square foot for standard epoxy coatings. Premium or designer finishes can range from $8 to $12 per square foot.

- Labor Costs: Installation encompasses surface preparation and coating application, leading to labor costs between $1 to $5 per square foot.

Durability and Maintenance:

Epoxy flooring is known for its durability, often lasting 15-20 years with proper care. This reduces the need for frequent replacements compared to conventional flooring, making it a cost-effective solution over its lifetime. Maintenance entails regular cleaning with mild detergents, largely devoid of expensive upkeep.

Enhanced Value:

Investing in epoxy flooring can enhance a property’s aesthetic appeal and functionality. Its resistance to stains, moisture, and heavy foot traffic makes it a practical choice for commercial and industrial settings.

Resale Attractiveness:

A well-installed epoxy floor can be a selling point, potentially increasing a property’s market value. Buyers often appreciate the industrial-grade resilience and the sleek finish it offers.

Cost-effectiveness:

Epoxy floors are energy-efficient due to their reflective nature, also reducing lighting needs. This can lead to decreased utility costs over time.

In conclusion, the long-term value and cost-saving aspects of epoxy flooring often justify the upfront investment, underlining its appeal as a smart and efficient flooring solution.

Service and Support

Bloomfield Epoxy Flooring prides itself on exceptional customer service and comprehensive support options that ensure client satisfaction and confidence. Each service package is tailored to meet specific project requirements, with a focus on quality and reliability.

Customer Service and Satisfaction

Bloomfield Epoxy Flooring offers a free consultation to potential clients to better understand their flooring needs and to showcase their professional approach. Their customer service team is dedicated to providing timely and attentive support throughout the entire flooring process, ensuring that every customer’s experience is seamless and satisfactory. Customer feedback is taken seriously and used to continuously improve the service quality.

- Professional Staff: Highly trained representatives who are both knowledgeable and courteous.

- Reliability: A commitment to prompt response and on-time project completion.

- Communicative: Clear, ongoing communication from initial consultation through to project completion.

Warranty and Guarantee Options

All flooring installations by Bloomfield Epoxy Flooring come with robust warranty and guarantee options. The company’s confidence in their work allows them to offer these assurances to their clients, which covers any unlikely defects in materials or workmanship.

-

Quality Material: Use of top-grade epoxy ensures durability and long-lasting finishes.

-

Fully Insured: Comprehensive coverage for all services provided, giving clients peace of mind.

-

Warranty Details:

Duration Coverage Conditions 1 Year Labor & Material Defects in installation 2 Years Material Only Defects due to material Variable Custom Solutions Tailored to client needs

Frequently Asked Questions

The cost of epoxy flooring, its potential drawbacks, and maintenance requirements are crucial considerations when exploring flooring solutions. The durability and suitability of epoxy flooring in various environments also play a significant role in the decision-making process.

What factors influence the cost of installing epoxy flooring?

The cost of installing epoxy flooring is influenced by factors such as the size of the area, the complexity of the design, the quality of materials used, and the labor fees. Additional prep work, such as repairing the concrete subfloor, can also impact the final price.

What are the potential drawbacks of choosing epoxy flooring for a home or business?

Epoxy flooring may be prone to scratching and can become slippery when wet if not textured properly. The installation process is labor-intensive and must be conducted precisely to avoid bubbles or uneven curing, and the strong fumes during application require proper ventilation.

Can epoxy flooring be considered a good investment in terms of durability and longevity?

Epoxy flooring is known for its resilience and can last for decades if installed correctly and maintained appropriately. Its resistance to stains, impact, and heavy traffic makes it a cost-effective investment over time.

How does the lifespan of epoxy flooring compare to other flooring options?

Epoxy flooring typically outlasts many traditional flooring options such as carpet, laminate, and vinyl, particularly in high-traffic or industrial environments. With proper care, its lifespan can compete with that of hardwood or tile flooring.

Is epoxy flooring suitable for all types of environments or conditions?

Epoxy flooring is ideal for environments that require easy-to-clean, durable surfaces, such as garages, basements, and commercial establishments. However, it may not be the best choice for areas prone to moisture issues without proper moisture mitigation efforts.

How do the maintenance requirements of epoxy flooring compare to traditional tiling?

Maintenance of epoxy flooring is relatively simple, requiring routine cleaning with mild soap and water. Unlike tiled floors, there is no grout to clean, and its seamless surface resists the accumulation of dirt and bacteria.